DIMENSIONS AND SPECIFICATIONS:

- Tube Diameter: The tube diameter typically ranges from 10 mm to 300 mm. Commonly used diameters include 25 mm, 50 mm, 75 mm, 100 mm, 150 mm, and 200 mm.

- Tube Length: Standard lengths are available from 500 mm to 6000 mm. Custom lengths can be manufactured upon request.

- Wall Thickness: Common wall thicknesses range from 0.5 mm to 5 mm. Frequently selected thicknesses include 1.0 mm, 1.5 mm, 2.0 mm, and 3.0 mm.

- Hole Diameter (Perforation Size): The hole diameter usually ranges from 0.5 mm to 20 mm. Popular hole sizes are 1 mm, 2 mm, 3 mm, 5 mm, and 10 mm.

- Open Area Percentage: The open area percentage typically varies between 20% and 60%, depending on the specific application requirements.

- Materials: Commonly used materials include stainless steel (grades 304, 316, 316L), brass, and copper.

- Hole Patterns: Perforations can be round, square, slotted, or hexagonal, chosen based on filtration efficiency or structural strength needs. The arrangement of the holes can be straight, staggered, or spiral.

- Customization: Customization is possible to meet specific client requirements for dimension tolerances and perforation patterns.

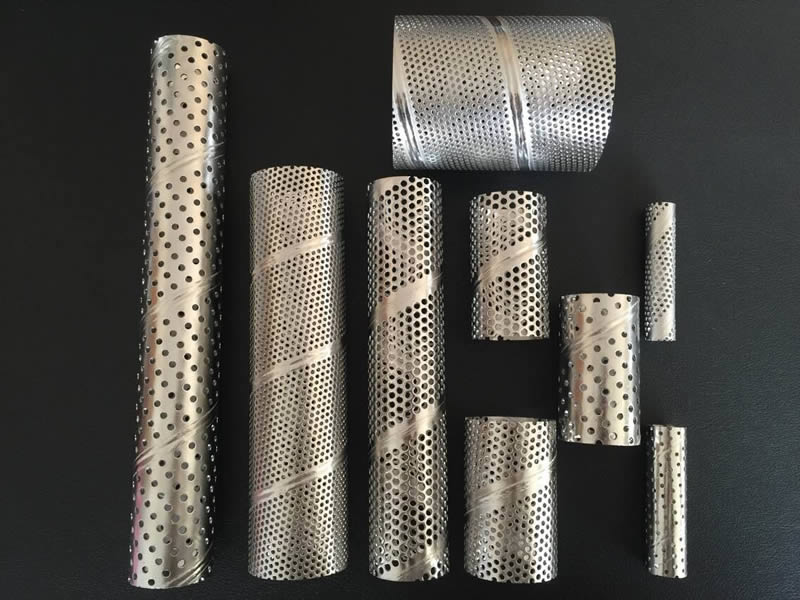

CUSTOMIZED PRODUCT ILLUSTRATIONS

Tube Diameter: 50–70 mm

Tube Length: 300–400 mm

Wall Thickness: 1.0–2.0 mm

Slot Dimensions: 1–2 mm wide × 10–15 mm long, arranged longitudinally

Open Area Percentage: 30–35%

Material: Stainless Steel 304 or 316

Hole Shape: Slotted (scale-shaped) perforations

Special Feature: Directional flow design with elongated slots providing controlled fluid filtration

Applications: Exhaust systems, directional filtration, acoustic control, automotive exhaust filtration, noise reduction systems, specialized industrial filtration.

Tube Diameter: 50–70 mm

Tube Length: 300–400 mm

Wall Thickness: 1.0–2.0 mm

Slot Dimensions: 1–2 mm wide × 10–15 mm long, arranged longitudinally

Open Area Percentage: 30–35%

Material: Stainless Steel 304 or 316

Hole Shape: Slotted (scale-shaped) perforations

Special Feature: Directional flow design with elongated slots providing controlled fluid filtration

Applications: Exhaust systems, directional filtration, acoustic control, automotive exhaust filtration, noise reduction systems, specialized industrial filtration.

PRODUCT INTRODUCTION

STAINLESS STEEL WIRE MESH SERIES

Includes woven, welded, crimped, and knitted meshes, made primarily from stainless steel grades 304, 316, for filtration, screening, security, and architectural applications.

FILTER WIRE MESH SERIES

Comprises extruder screens, filter discs, sintered meshes, wedge wire screens, and perforated filter elements, primarily used in chemical, industrial, and petroleum filtration processes.

COPPER MESH SERIES

Consists of woven copper mesh, knitted copper mesh curtains, and decorative copper meshes, extensively applied in shielding, insect screening, decorative interiors.

TITANIUM WIRE MESH SERIES

Covers woven titanium meshes, knitted titanium mesh, and titanium perforated metal sheets, primarily utilized in chemical processing, aerospace, marine, medical, and filtration applications.

SAFETY MESH SERIES

Encompasses welded wire fences, expanded metal mesh panels, gabion basket barriers, and heavy-duty security meshes, used in construction, perimeter protection and slope stabilization projects.